Side Projects / Designing Speakers

This is the story of the best class I ever attended, during my 2nd year of my Ph.D. at USC (2004). The vice president of research and development of JBL came to USC to teach a one-time course on building a loudspeaker. The class was amazing because not only because we built something with our own hands, but at the end we also kept the class project (2 speakers), which I have been using as my main living room speakers since then! The pictures below are from the final presentation we did, which took place at JBL’s Northridge headquarters. We also had a tour of their facilities and tested various speaker designs, and also had our own speakers measured in a proper anechoic chamber.

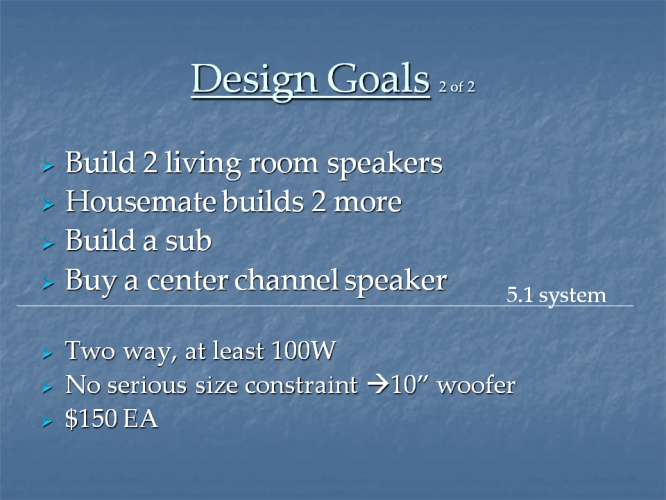

Here are the targets. Two speakers for use in the living room. The idea was that Andrew, my roommate, would build two more, and then we would buy a center speaker and a sub and have a 5.1 system. At the end, Andrew built only one speaker (and by no means a “satellite” since it was a humongous, 3-way failure :-) ). But, we used the spare parts to put together a subwoofer box (the sub needs no electronic filters!), which we combined with a woofer and a sub-amplifier. We bought the center and two satellite speakers anyway.

These are simply the drivers (transducers) I used. I bought them as-is. The point of the class was to build a nice box and also the filters required to combine the two drivers. The woofer would produce the low frequencies, and the tweeter would produce the high frequencies.

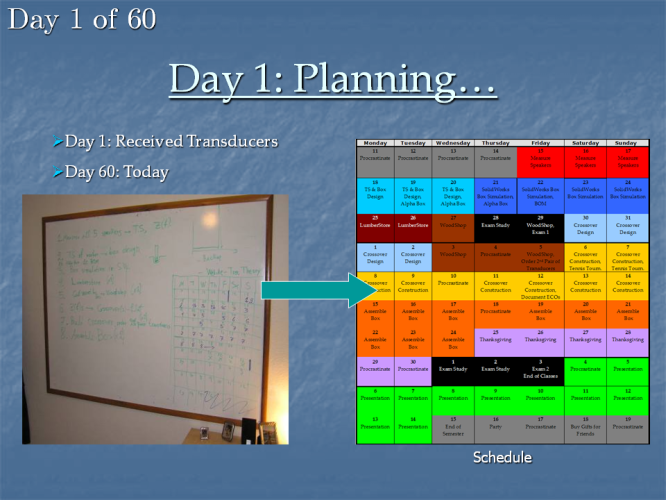

First step: planning! Starting with day 1 when I received the transducers, until day 60 which was the JBL presentation. Includes de sing, measurements, holidays, exam studies, and preparing the presentation!

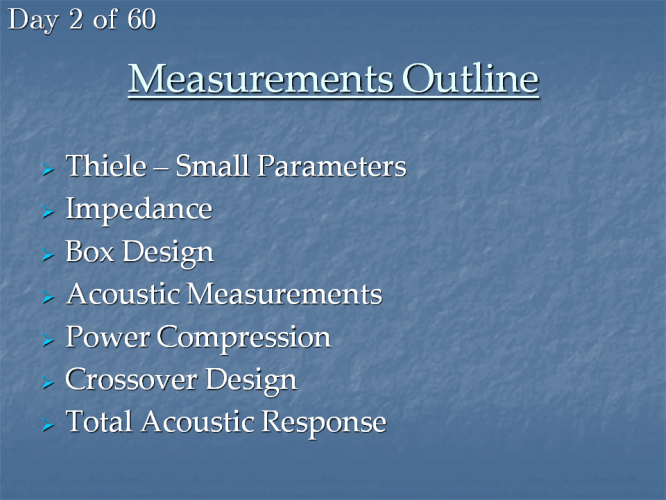

On day 2 I started measuring the transducers in the class. Above is a list of all the necessary elements: Thiele-Small parameters, impedance, box, acoustic response, power compression, crossover performance, and total acoustic response (this is the drivers + crossover).

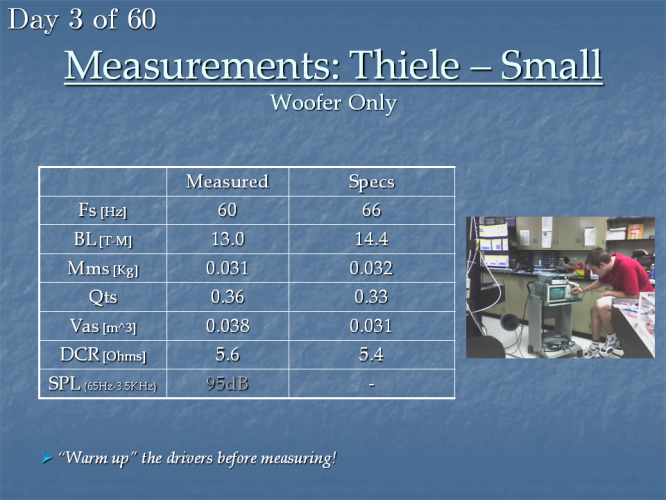

In this table you see the differences between measured parameters and pre-specified ones from the manufacturer. So, don’t believe everything you read in spec sheets because there are manufacturing variations in all the products.

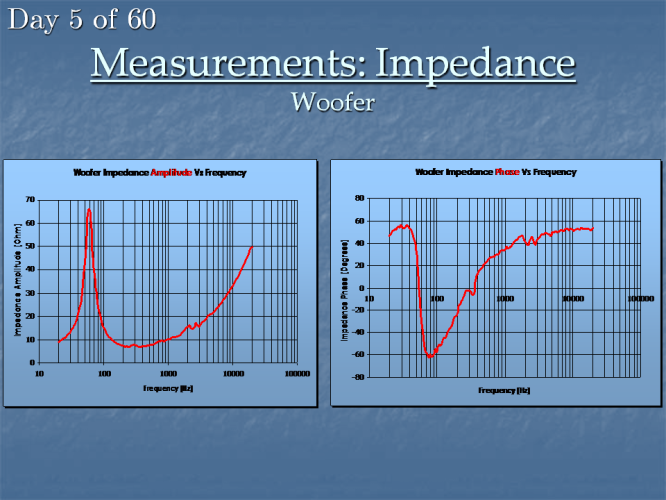

Here is some of the most interesting measurements. We apply a voltage 1V*sin(ωt), and we vary the input frequency. The impedance of the driver is recorded for every frequency. You see that the amplitude has a sharp peak, which is a resonant peak for the woofer (resonant frequency). At the resonance, as with all resonances in nature, the phase (right panel) crosses 0.

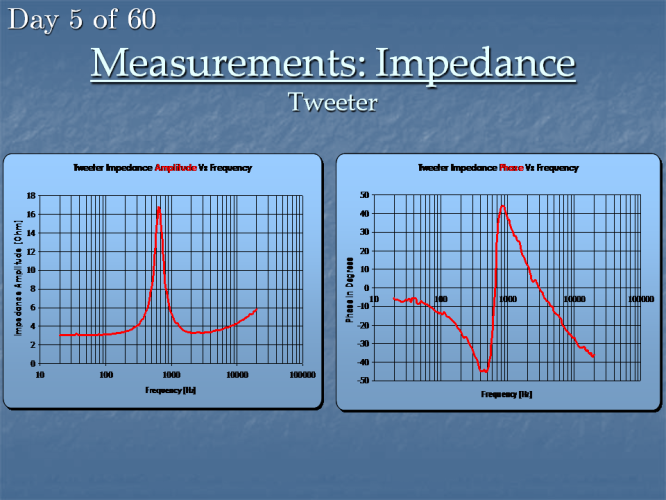

Same set of measurements for the tweeter. Notice that the resonant frequency is now higher, thus allowing the tweeter to produce the high frequency range.

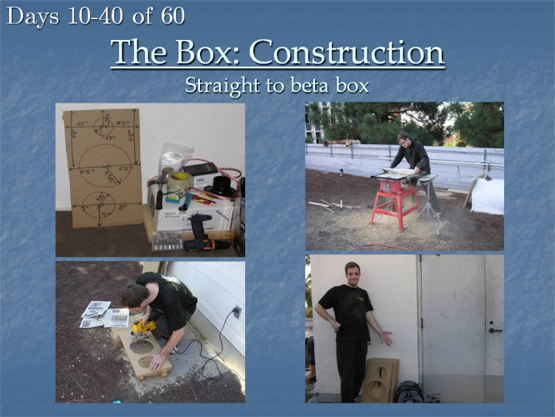

That was fun. We bought huge pieces of wood (medium density fiberboard - MDF) from a local lumberyard, which we then cut into smaller pieces using the class’ sawing machine (we burnt it down once, but that a whole other story). See on the top left panel my drawings for the holes: tweeter goes in the top, woofer in the middle, and the last hole is for the vent (the vent amplifies low frequencies). The construction took about 2 weeks.

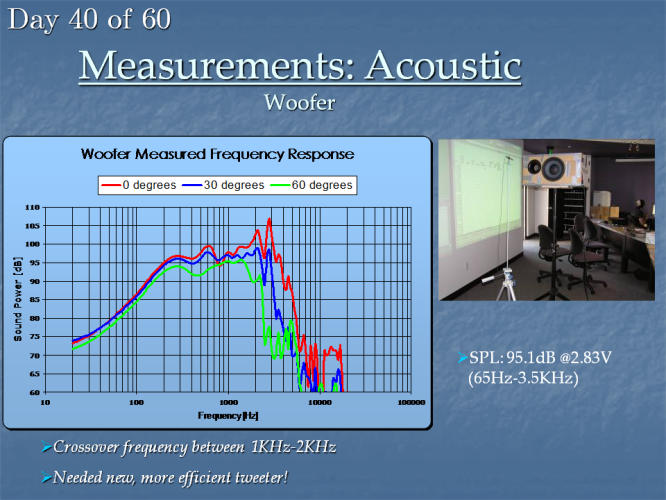

After roughly mounting the woofer in the box (put together with duct tape for now!), we measure the response at 3 different angles from the center. Again, we put a 2.83V*sin(ωt) signal for input and vary the frequency, but this time we have a microphone 1m away from the box and record the audio signal. As long as the microphone is linear (a $600 one is), a perfect speaker would produce a straight line as a function of frequency, thus reproducing every audio frequency perfectly. Of course, in reality not speaker produces a straight line (see my graph above), and thus all the design and money goes into making the response as flat as possible. Also, notice how off-axis the performance of the speaker is worse!

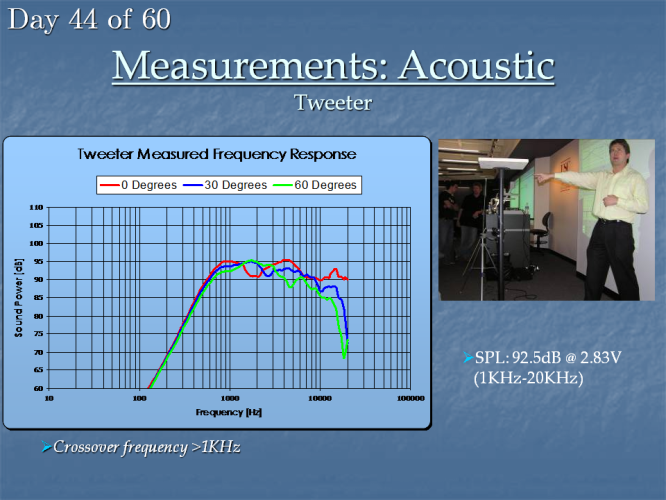

Here is the same graph for the tweeter. Notice that the level of the amplitude is at 92.5dB on average (around where it is more flat), while at the woofer was at 95.1dB. This is a problem, it means that the low frequencies of the woofer will be twice as loud compared to the tweeter when the two are put together. This is usually solved by adding a resistor at the woofer to damp some of its energy into heat, however this also alters its response at other frequencies. It becomes complicated to balance the two drivers exactly!

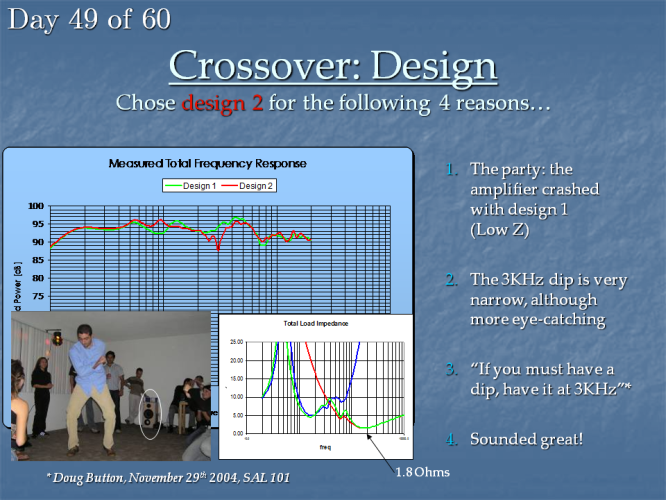

When the crossover was theoretically simulated, I had two options to choose from, and they produced the total response (for my specific drivers) shown in the picture. I chose the second design (red curve) since the first one had a very low total impedance (1.8 Ω at a frequency), and thus whenever there was a loud song that had a lot of frequency content around that range, it would draw too much current from the amp and it would crash. The red curve had a small dip at 3 KHz, but since the human ear (another nonlinear device) is super sensitive at that that frequency range (that’s where human voice mostly lies), I decided I could live with it.

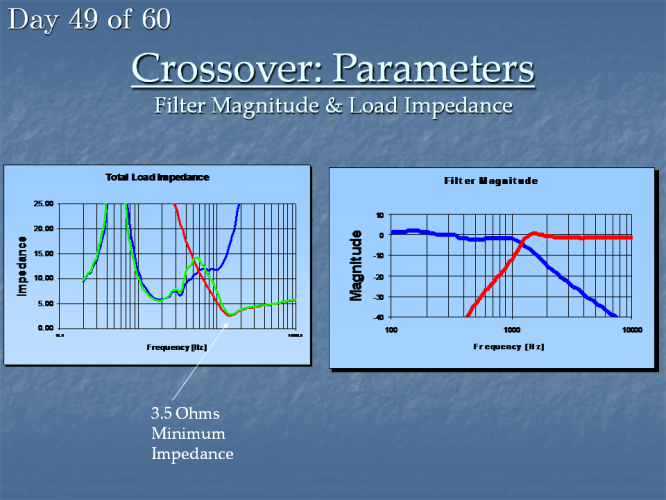

The new crossover design produced a minimum impedance of 3.5 Ω, and you can see its response on the right panel. It consists of two filters, a low-pass one for the woofer (blue line) and a high-pass one for the tweeter (red line). The filters are connected to the drivers, and the input audio signal is split and fed into each filter+driver separately. The total audio signal heard is basically the sum of the two then.

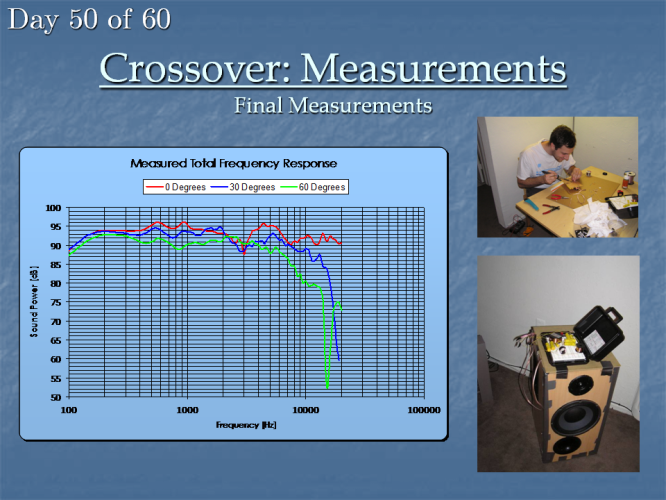

You can see the crossover design in the bottom right image, and the total measured frequency response for 3 angles in the main graph. Notice the dip on-axis at 3 KHz, as predicted. However the dip goes away off-axis, and the total response becomes extremely flat for this speaker!

Here is the final design after adding vents, handles, glue, feet, and proper input connectors, times 2!

On the last day, I prepared the presentation… At JBL not only did they measure our speakers at a chamber, but they also did blind tests: a random speaker would be placed behind a sound-transparent but not light-transparent screen (so we could hear but not see the speakers), and we would listen to it independently and rank it from 1-10. A professional audio specialist (the best ear in town) also ranked them. My speaker got a 6/10, which is great since 8/10 was their reference JBL speaker (from the Infinity series) and 9/10 and 10/10 usually go to $10K-priced speakers. The total cost was $600 for the pair, but this is just materials as labor was free. There is no safe comparison with commercial mass-produced speakers though, since the companies buy the materials very cheaply in bulk but they have to pay a lot for the labor - exactly the opposite from my situation here.

That was it! I’ve been using these speakers since then.

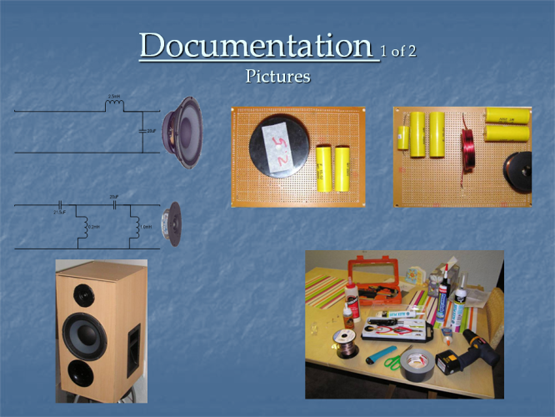

Here is the documentation. Pictures of the crossover designs, the tools, and the two filters. They’re simply some capacitor and inductors put together (albeit huge ones to withstand 100 W power through them).

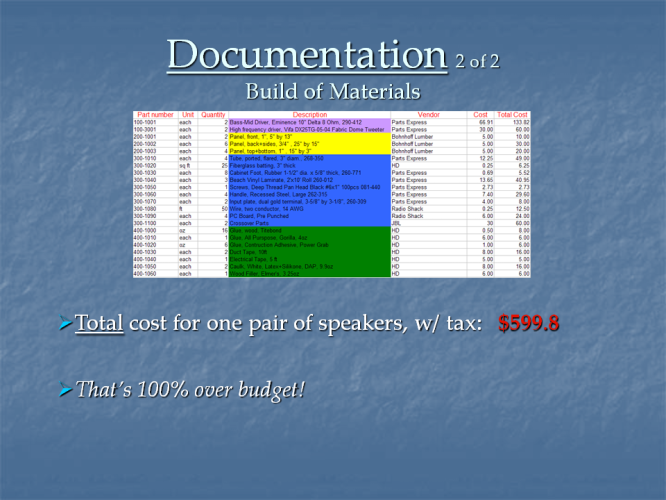

Here is a build of materials, a list of all the components I needed to make the speakers. It looked silly back then, but in retrospect it was a very wise decision as I now know exactly what I would need to build something similar again.

Total cost was $600 for the pair, but this is just materials as labor was free :-) There is no safe comparison with commercial mass-produced speakers though, since the companies buy the materials very cheaply in bulk but they have to pay a lot for the labor - exactly the opposite from out situation here.